| Anmol Chemicals is the pioneer manufacturers of Calcium Undecylenate & Zinc Undecylenate or Undecenoate, Pharmaceutical Excipients Food & Flavor chemicals in India. We offer Halal and Kosher Calcium Undecylenate & Zinc Undecylenate or Undecenoate made in an ISO9001, ISO22000 (FSSC22000) and cGMP certified facility. Our group has several manufacturing facilities spread across the world, supported by toll manufacturers and representatives in UAE, Europe, Africa, USA, China and has several associated manufacturing facilities spread across India. All the Information on Physics, Chemistry, Applications, Uses and Technology on Manufacture of Calcium Undecylenate & Zinc Undecylenate or Undecenoate is in these pages. |

| The units have one or more of the certifications like FDA GMP, ISO 9001, ISO 22000, HACCP, REACH, Kosher & Halal |

Calcium Undecylenate or Undecenoate USP & Commercial Pure Grade Manufacturers

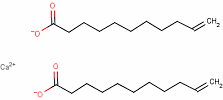

Calcium Undecylenate or Calcium Undecenoate CAS Number: 1322-14-1

Calcium Undecylenate or Undecenoate SDS GHS, MSDS Sheet of Manufacturers

Calcium Undecylenate USP Grade

C22H38O4Ca -- 406.61

10-Undecenoic acid, calcium (2+) salt.

Calcium 10-undecenoate.

Calcium Undecylenate contains not less than 98.0 percent and not more than 102.0 percent of C22H38O4Ca (calcium undecylenate), calculated on the dried basis.

Packaging and storage: Preserve in well-closed containers.

Identification

A: A filtered solution (1 in 20) in 3 N hydrochloric acid responds to the tests for Calcium.

B: Transfer 40 mL of water and 10 g of calcium undecylenate to a 250-mL separator. Cautiously and slowly add 10 mL of hydrochloric acid, while swirling. Insert the stopper, and shake. [NOTE—The separator will become quite warm, and pressure must be carefully and frequently relieved through the stopcock. If a curdy, white material remains after 5 minutes of shaking, add additional hydrochloric acid, 1 mL at a time, and shake until a clear oily phase is formed.] Allow the phases to separate, drain, and discard the bottom aqueous layer. Drain and discard the middle oily layer, if present. Filter the top layer of undecylenic acid through a pledget of cotton into a 10-mL graduated cylinder, noting the volume obtained. Transfer the filtrate to a 250-mL flask, and add an equal volume of aniline. Reflux for 1 hour, swirling the flask occasionally. Allow to cool, and pour 60 mL of alcohol through the condenser into the flask. Remove the flask from the condenser, add 1 g of charcoal, and stir. Filter the slurry into a 250-mL beaker. Add water drop-wise until a few crystals form or the solution becomes slightly cloudy. [NOTE—If too much water is added, an oil will form. Add alcohol dropwise until the oil dissolves.] Allow the mixture to stand or refrigerate until crystals are formed. Collect the crystals on a filter paper inserted in a 45-mm porous glass filter funnel. Wash the crystals with 75 mL of 25% alcohol: the crystals have a clean, white, glossy appearance. If not, re-crystallize by dissolving the crystals in about 50 mL of alcohol. Add about 1 g of charcoal, stir, filter into a 150-mL beaker, and continue as directed above, beginning with “Add water dropwise.” Dry the crystals in vacuum at 50C for 2 hours: the crystals so obtained melt between 66 and 67.5. [NOTE—If the melting point is low, additional drying or recrystallization may be necessary.]

Loss on drying: Dry it at 105 for 2 hours: it loses between 2.0% and 5.7% of its weight.

Particle size, Method: Test in accordance with this procedure, except to use not more than 25 g, and except that a single No. 100 sieve is used and is to be shaken for not less than 30 minutes or until sifting is practically complete: not less than 99.0% of it passes through a No. 100 sieve.

Limit of free undecylenic acid: Transfer 10 g of Calcium Undecylenate, accurately weighed, to a 400-mL beaker, add 250 mL of solvent hexane, and mix for 2 hours using a magnetic stirrer. Filter into a 500-mL flask, evaporate with the aid of a current of air to about 20 mL, and add 100 mL of neutralized alcohol. Add 3 drops of phenolphthalein TS, and titrate with 0.1 N sodium hydroxide. Each mL of 0.1 N sodium hydroxide is equivalent to 18.43 mg of C11H20O2: not more than 0.1% is found.

For Original Monographs of IP Indian Pharmacopoeia BP British Pharmacopoeia USP US Pharmacopoeia FCC Food Grade product, please check with the respective web-pages or books.

Manufacturers

Anmol Chemicals

S-8, SARIFA MANSION, 2ND FLANK ROAD, CHINCHBUNDER, MUMBAI 400009, INDIA

TEL: (OFFICE) 91-22-23770100, 23726950, 23774610, 23723564. FAX: 91-22-23728264

e-mail: anmolc@mtnl.net.in

Exports to USA, Canada, UAE, Dubai, South Africa, Tanzania, Kenya, Nigeria, Egypt, Uganda, Turkey, Mexico, Brazil, Chile, Argentina, Europe UK Netherlands, Italy, Spain, Germany, Portugal, France, Malaysia, Indonesia, Thailand, Korea, Japan, etc.

Copyright and Usual Disclaimer is Applicable. 22 February, 2022